From Idea to Product in a Single Step

Designed for rapid prototyping and low-volume production. We reduce your R&D risks and molding costs with flexible solutions.

Designed for rapid prototyping and low-volume production. We reduce your R&D risks and molding costs with flexible solutions.

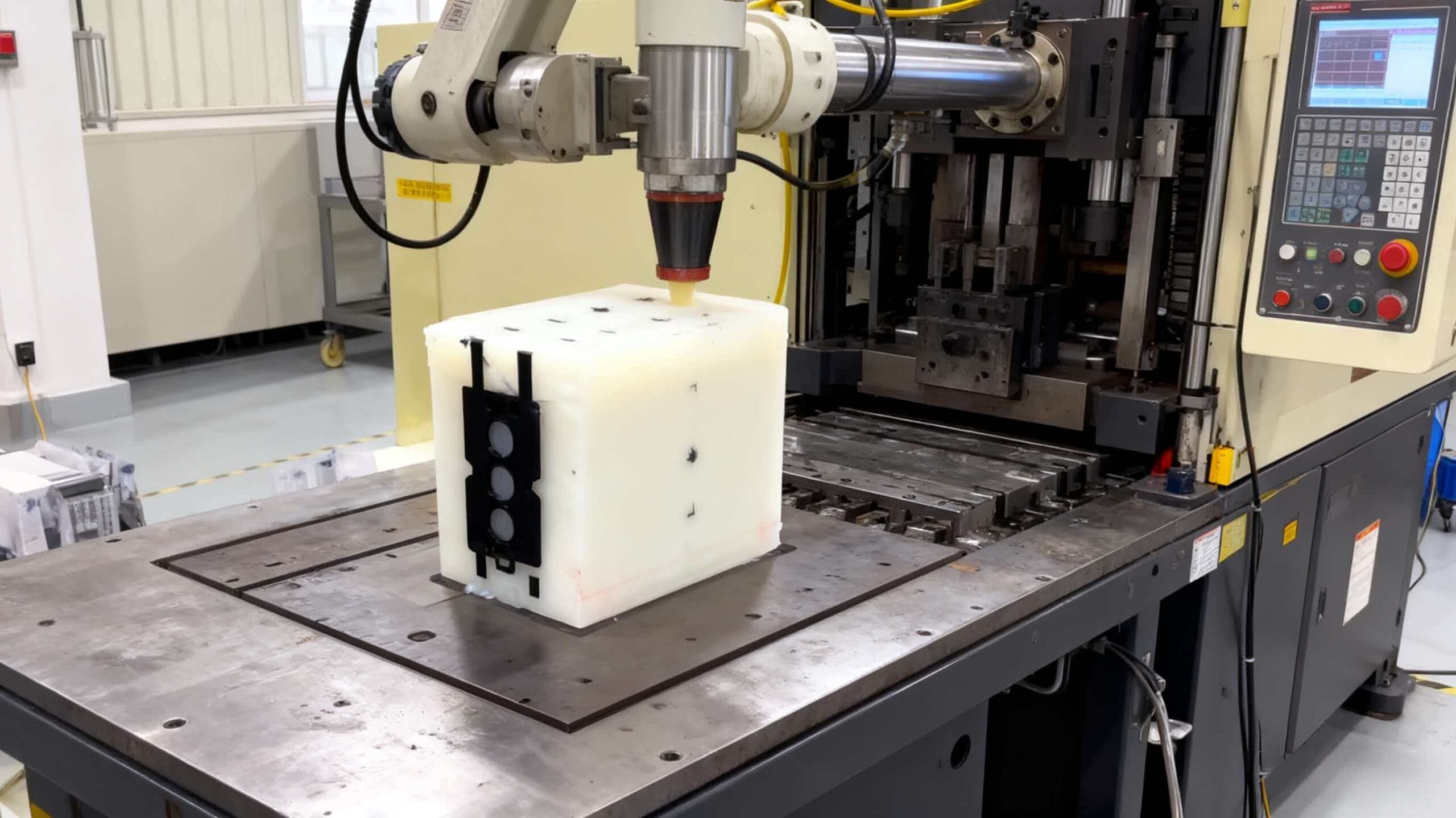

The ultimate solution for rapid, high-fidelity prototypes and small-batch custom parts. Go from 3D model to functional sample, often within 24 hours.

Ideal for producing large, durable, yet lightweight parts like equipment enclosures and automotive panels. A cost-effective solution for mass production.

Whether you need high-detail flexible parts or large, durable enclosures, we have the leading-edge solution.

An outdated choice for rapid innovation and small-batch production.

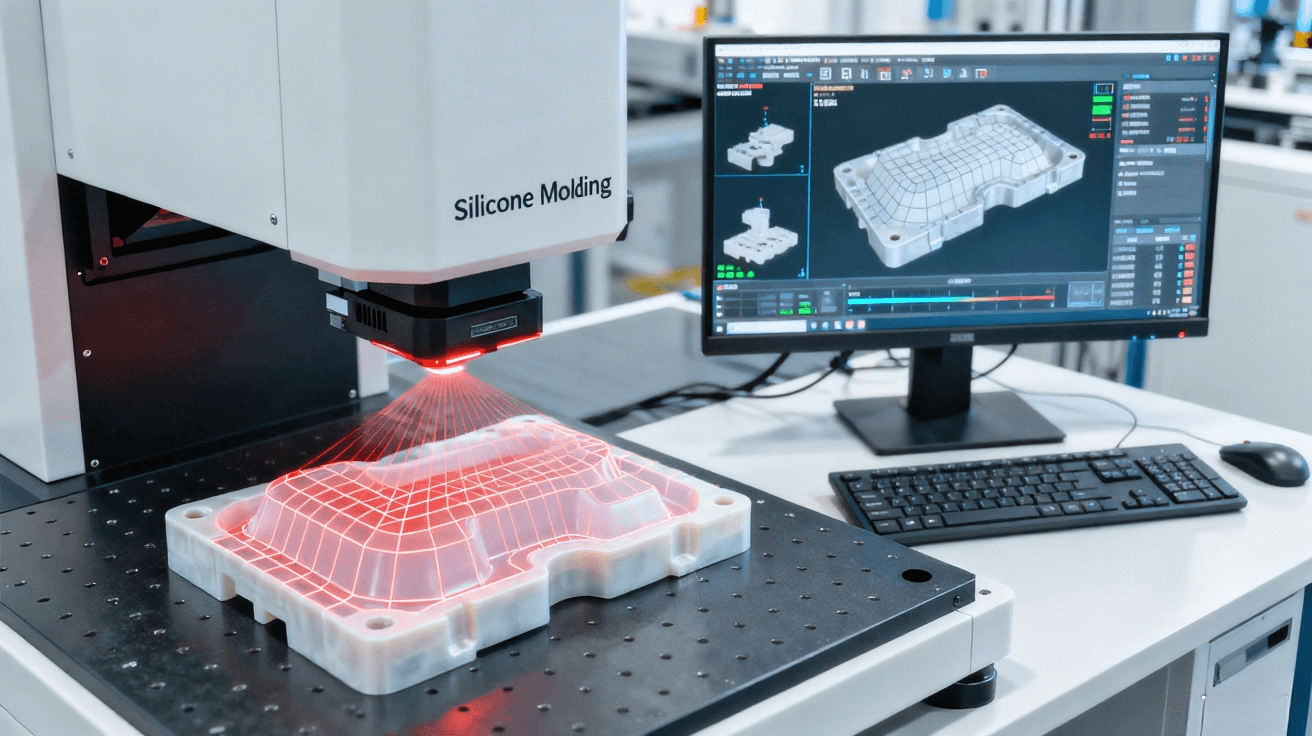

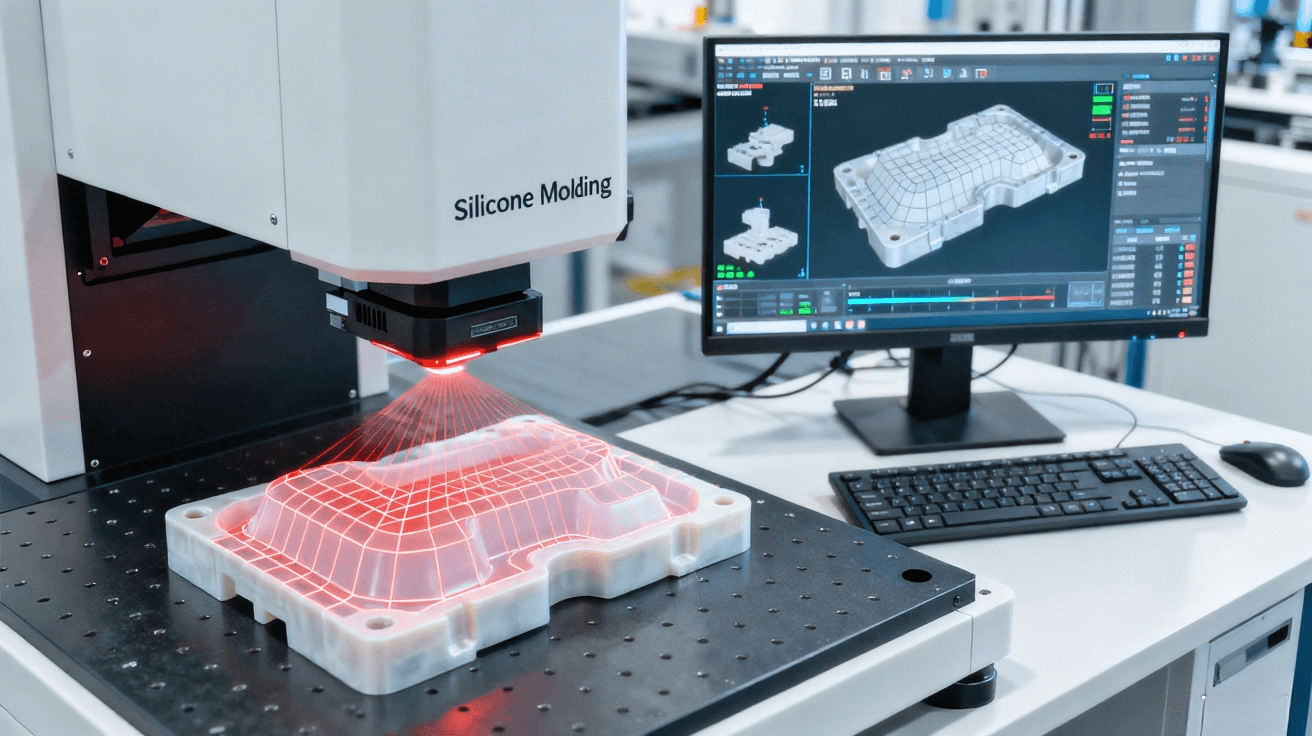

From raw materials to final inspection, watch how our advanced manufacturing processes deliver superior results for your projects.

Follow our professional, worry-free process to bring your project to life.

Have questions? We've got answers. Find what you're looking for below.

No problem at all! Our expert engineering team can work with you from a sketch, a concept, or even just an idea. We can help you create professional 2D/3D models ready for production. Contact us to start the design process.

Vacuum forming is excellent for larger parts with less stringent tolerances, while silicone injection molding offers very high precision, suitable for intricate details and complex geometries. We will always recommend the best and most cost-effective option based on your specific project needs.

It depends on the process. For rapid prototyping services like urethane casting or 3D printing, we can start from a single piece (MOQ=1). For larger production runs, we will provide a detailed and competitive quote based on your quantity requirements.

We offer a wide range of materials. For vacuum forming, we use plastics like ABS, PC, PETG, and HIPS. For silicone molding, we have various grades of silicone rubber with different hardness levels (Shore A), colors, and properties (e.g., food-grade, high-temperature resistant).

Typically, a prototype sample can be produced and ready for shipment within 7-14 business days. The exact lead time depends on the complexity of your design, the chosen manufacturing process, and our current production schedule. We will provide a precise timeline with your quote.